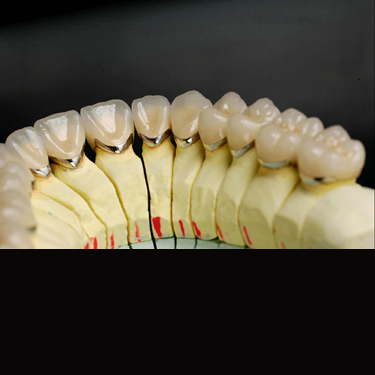

Rely on us for outstanding PFMs, while appreciating our wealth of technical knowledge, superb customer support and quick

three-day turnaround for copings. We apply the latest technology in processing your PFM restorations to ensure consistently ideal fit, contacts and occlusion, and lifelike esthetics.

For even greater case-to-case consistency, order our digitally manufactured PFMs. Designed and contoured using CAD/CAM

technology. CAD/CAM PFMs seat with little to no chairside adjustment thanks to digital equilibrated occlusion, virtually perfect

contacts and beautifully consistent anatomy.

Our goal is to ensure that every case you send to our laboratory will exhibit consistently ideal fits, contacts and occlusion, and

provide your dentists with esthetics that will seat with little to no chairside adjustment. All PFM copings and bridge frameworks are carefully waxed to your prescribed contours and trimmed margins, then invested using computer-controlled dosing of investment mixed with an orbital centrifugal mixer. A multi-stage burnout and induction casting ensure a consistent fit. Save time and labor

when you outsource porcelain fused to metal restorations.